-

Pneumatic Ball Valve

-

Pneumatic Butterfly Valve

-

High Pressure Ball Valve

-

Marine Butterfly Valve

-

Ventilation Butterfly Valve

-

Damper Valve

-

FB Ball Valve

-

High Temp Ball Valve

-

Industrial Butterfly Valve

-

High Temperature Pneumatic Valve

-

High Temperature Globe Valve

-

Vacuum Ball Valve

-

Special Purpose Valves

-

Threeway Valve

-

RTO Valve

-

Pneumatic Actuator

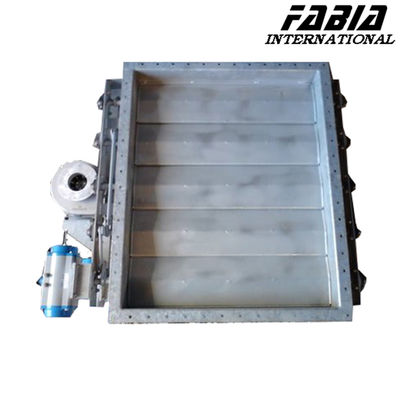

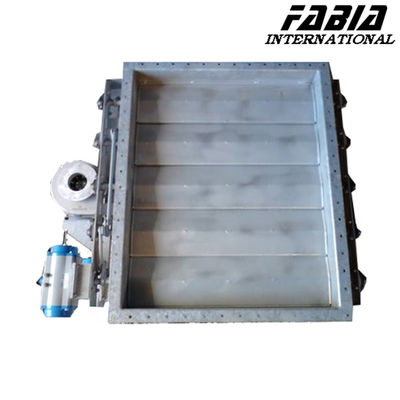

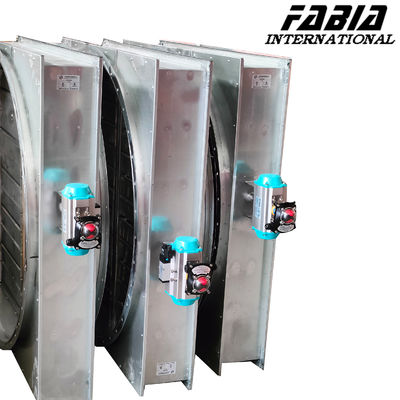

Pneumatic Flue Flapper Valve Stainless Steel Gas Flapper Valve

| Place of Origin | China |

|---|---|

| Brand Name | FABIA |

| Certification | ISO9001,CE,CCS,DNV |

| Model Number | 1/8 inch ~ 36 inch |

| Document | Product Brochure PDF |

| Minimum Order Quantity | 1 set |

| Price | Negotiable |

| Packaging Details | Cartons/Wooden cases |

| Delivery Time | 15-30 work days |

| Payment Terms | L/C, D/A, D/P, T/T, MoneyGram, Western Union |

| Supply Ability | 100-1000 set per week |

| Product Name | Pneumatic Flue Flapper Valve | Type | Damper Valve |

|---|---|---|---|

| Material | Stainless Steel | Actuator | Pneumatic |

| Control Mode | Pneumatic | Application | Petroleum, Chemical, Power, Etc. |

| Connection | Stainless Steel | Pressure | 20MPa |

| Temperature | 1000℃ | ||

| Highlight | gas flapper valve,Stainless Steel gas flapper valve,Pneumatic Flue Flapper Valve |

||

FABIA Pneumatic Flue Flapper Valve Stainless Steel Flue Flapper Valve

1. Description:

Gas baffle valve is mainly used in the inlet, outlet or bypass flue of the absorption tower of the flue gas desulfurization system to isolate the flue gas flow, and can also be used in other flue gas pipelines with high operational isolation requirements, with no internal leakage and leakage after closure, good sealing, no air leakage and leakage phenomenon.

High temperature does not deform, does not accumulate soot, the switch is flexible during normal operation, no jam phenomenon, low resistance, hydraulic drive, high stability.

2. Specification:

| FABIA Valve Parameter List | ||

| Valve type: | Pneumatic Flue Flapper Valve Stainless Steel Flue Flapper Valve | |

| Size: | 1/8 inch ~ 18 inch | |

| Material: | WCB,GGG40,FCD,SS304,SS304L,SS316,SS316L,ST37(Q235B),SS410 | |

| Connection type: | Butt /Flange Connection | |

| Driving model: | Manual/Worm gear drive/Pneumatic/Electric | |

| Pressure rating: | PN0.1~PN16 | |

| Temperature: | -40℃~1000℃ | |

| Model: | FB-DB.......... | |

3. Features:

- Normal operation is driven by hydraulic pressure, the pressure can reach 20 MPa, the thrust can reach more than 17 tons, the tension can reach more than 13 tons, the power is large, the flexibility to overcome the resistance is strong, the switch is flexible, no jam phenomenon, and the stability is high.

- Combination of soft seal and hard seal, soft seal for high temperature silicone plate, hard seal for 316L stainless steel plate special track, no internal leakage or external leakage, to ensure zero leakage, 100% air tightness, and increase the sealing when necessary.

- Switch position can realize the remote transmission of electrical connection. Field control box with position indication. The power supply adopts the original power supply of the distribution room. At the same time, it can be remotely connected to the DCS control system of Party A to achieve local and remote control, and the on-off signal can be connected with the DCS.

- Factory is equipped with oil cylinder, oil station, electric control box, a complete set of two-way anti-flange, and connected with the valve by bolts, and the gap seal is the disc seal. After arriving at the site, the flange can be welded directly to the field flue, simple installation, short cycle, can be completed in a small maintenance period.

- Open state: the insert plate is outside the flue, avoiding the corrosion of high temperature smoke and medium, which not only reduces the resistance of the smoke circulating in the flue, but also ensures the service life of the insert plate. Closed state: The insert plate is made of carbon steel, lined on both sides with 316L stainless steel plate or other corrosion resistant steel plate to ensure the service life of the valve.

![]()

![]()