-

Pneumatic Ball Valve

-

Pneumatic Butterfly Valve

-

High Pressure Ball Valve

-

Marine Butterfly Valve

-

Ventilation Butterfly Valve

-

Damper Valve

-

FB Ball Valve

-

High Temp Ball Valve

-

Industrial Butterfly Valve

-

High Temperature Pneumatic Valve

-

High Temperature Globe Valve

-

Vacuum Ball Valve

-

Special Purpose Valves

-

Threeway Valve

-

RTO Valve

-

Pneumatic Actuator

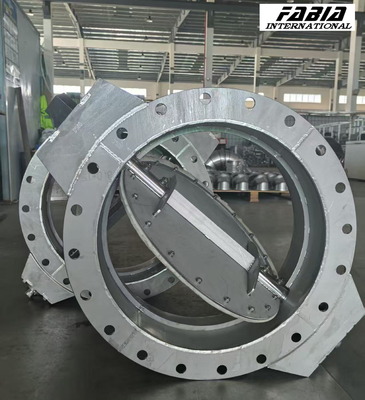

Flue Gas Butterfly Valve Industrial Butterfly Valve Air Valve

| Place of Origin | China |

|---|---|

| Brand Name | FABIA |

| Certification | ISO9001,CE,CCS,DNV |

| Model Number | 1/8 inch ~ 36 inch |

| Document | Product Brochure PDF |

| Minimum Order Quantity | 1 set |

| Price | Negotiable |

| Packaging Details | Cartons/Wooden cases |

| Delivery Time | 15-30 work days |

| Payment Terms | L/C,D/A,D/P,T/T,MoneyGram,Western Union |

| Supply Ability | 100-1000 set per week |

| Product Name | Pneumatic Industrial Butterfly Valve | Valve Material | Stainless Steel |

|---|---|---|---|

| Valve Type | Eccentric Butterfly Valve | Valve Connection | Flange |

| Valve Operation | Pneumatic | Valve Application | Ventilation |

| Valve Pressure | 150-300 PSI | Valve Sealing | Soft Sealing |

| Valve Size | 2-36 Inch | Valve Temperature | 0-1000℃ |

| Highlight | industrial flue gas butterfly valve,ventilation air butterfly valve,butterfly valve with warranty |

||

Core Working Principles of Flue Gas Butterfly Valves:

- Rotational Control Mechanism:

The disc rotates 90° to achieve rapid opening/closing and flow regulation. The bidirectional flow design accommodates both forward and reverse media directions. - Actuation & Positioning:

The electric actuator precisely controls the rotation angle via motor drive and gear reduction, ensuring responsive operation. Internal limit switches guarantee accurate positioning. - High-Temperature Sealing Optimization:

Planar sealing between the disc and seat—combined with elastic material seats—automatically adjusts contact pressure, thus ensuring reliable sealing integrity in high-temperature flue gas environments (e.g., desulfurization systems). -

Introduction to Flue Gas Butterfly Valves

Flue gas butterfly valves are specialized control valves designed for high-temperature, high-pressure, and corrosive gas media (e.g., flue gas, dust, hot air). Widely used in industrial ventilation, environmental dust removal, and energy systems, they are systematically introduced below across five aspects: core definition, working principles, structural types, key features, and typical applications.

-

Definition & Overview

Flue gas butterfly valves utilize a circular disc structure to regulate, divert, merge, or switch media flow via rotational motion. They are primarily deployed in harsh environments such as high-temperature flues and desulfurization systems. Core functions include flow regulation, pressure control, and media isolation, offering advantages of low flow resistance, rapid actuation, and ease of maintenance.

-

Working Principles

The valve operates via an external drive (e.g., manual lever, electric/pneumatic actuator) rotating the valve stem to move the disc between 0° (closed) and 90° (open):

- Open/Close Control:

- Parallel to pipeline axis: Full open (minimal flow resistance).

- Perpendicular to axis: Fully sealed (zero media leakage).

- Sealing Mechanism:

- Disc and seat form a sealing interface via planar sealing or elastic materials (e.g., EPDM rubber).

- In closed position, the seat deforms under compression to generate sealing pressure (leakage class up to ANSI Class VI).

- Actuation Modes:

- Manual: Adjust opening via handwheel scale.

- Electric/Pneumatic: Actuator receives 4–20mA signals for precise flow control and automated operation.

-

Structure & Classifications

Classified by eccentricity design:

- Centerline Type:

Stem aligns with disc center; bidirectional sealing; ultra-low flow resistance; ideal for low-pressure, high-flow systems (e.g., ventilation ducts). - Eccentric Type:

- Single/Double/Triple-offset designs reduce friction and enhance seal durability under high pressure/temperature (e.g., triple-offset suits extreme temperatures ≤650°C).

- Material Selection:

- Body: Carbon steel/stainless steel.

- Disc/Seal Ring: Corrosion/wear-resistant alloys (304H stainless steel, duplex steel, Hastelloy®).

- Seat: Tungsten carbide overlay for abrasion resistance.

- Innovative Designs:

- Four-bar linkage mechanism (drive arm, driven arm, etc.) vertically lifts the disc away from the seat during operation, minimizing friction and distributing pressure evenly to extend seal life.

- Centerline Type:

- Open/Close Control:

1. Specification:

| FABIA Valve Parameter List | ||

| Valve type: | Flue Gas Butterfly Valve Industrial Butterfly Valve | |

| Size: | 2 inch ~ 36 inch | |

| Material: | WCB,GGG40,FCD,SS304,SS304L,SS316,SS316L,ST37(Q235B),SS410 | |

| Connection type: | Butt /Flange Connection | |

| Driving model: | Manual/Worm gear drive/Pneumatic/Electric | |

| Pressure rating: | PN0.1~PN16 | |

| Temperature: | -40℃~700℃ | |

| Model: | FB-DB.......... | |